Silver Mercury Applications in Modern Gold Extraction

Silver mercury, often referred to as high-purity or „German silver mercury,“ is a specialized form of elemental mercury valued for its exceptional purity (typically 99.999%) and fluid properties. In the context of gold extraction, it plays a role in the traditional amalgamation process, where mercury binds with fine gold particles to form an amalgam. This allows for efficient recovery of microscopic gold from ore, particularly in artisanal and small-scale gold mining (ASGM) operations. While modern industrial gold extraction has largely shifted to cyanide leaching and other methods, silver mercury remains relevant in certain applications due to its effectiveness for small-scale and placer mining.

In 2026, amid rising gold prices and ongoing demand from ASGM sectors in regions like Africa, South America, and Asia, understanding silver mercury’s applications is essential for researchers, miners, and environmental regulators. However, its use is heavily regulated under the Minamata Convention on Mercury, which seeks to phase out mercury in mining due to severe health and environmental risks.

The Amalgamation Process: How Silver Mercury Works in Gold Extraction

The core principle of mercury amalgamation involves mercury’s unique ability to wet and alloy with gold (and to a lesser extent silver) at room temperature, forming a stable mercury-gold amalgam. This process is particularly effective for recovering very fine gold particles that gravity methods alone might miss.

Key steps in the process:

- Ore Preparation: Crushed ore or alluvial material is concentrated via sluicing, panning, or gravity separation to isolate gold-bearing concentrates.

- Amalgamation: High-purity silver mercury is added to the concentrate. The mercury selectively binds to liberated gold particles, forming a dense amalgam that separates from waste material (gangue).

- Separation and Recovery: The amalgam is collected, and the mercury is evaporated (often by heating in a retort or open pan), leaving behind „sponge gold“ for further refining. Retorts can recapture much of the mercury for reuse, reducing losses.

- Variants: Internal amalgamation occurs during grinding (e.g., in ball mills), while external amalgamation uses separate mixing boards or barrels.

Silver mercury’s ultra-high purity minimizes impurities in the final gold product and improves amalgamation efficiency compared to lower-grade mercury. It is especially suited for ASGM where low-cost, simple tools are preferred.

Advantages of Silver Mercury in Modern Applications

- High Recovery for Fine Particles: Effective for micron-sized gold in placer deposits or tailings.

- Low Capital Requirement: Requires minimal equipment—ideal for small-scale operations.

- Rapid Process: Quick amalgamation allows faster throughput in remote sites.

- Purity Benefits: German-sourced or refined silver mercury ensures cleaner amalgams and higher-quality gold output.

Despite these benefits, industrial-scale mining has moved away from mercury due to superior recovery rates (often >90%) from cyanidation and environmental compliance.

Health and Environmental Concerns

Mercury amalgamation remains the largest anthropogenic source of mercury pollution globally, with ASGM contributing hundreds of tonnes annually. Vaporized mercury from heating amalgams poses severe risks:

- Neurological damage, kidney issues, and developmental effects in exposed miners and communities.

- Bioaccumulation in aquatic ecosystems, contaminating fish and food chains.

- Long-term soil and water pollution from tailings.

The Minamata Convention drives reductions, with many countries promoting mercury-free alternatives like borax smelting, enhanced gravity concentration, or cyanide alternatives. By 2026, global mercury use in ASGM is declining, though it persists in unregulated areas.

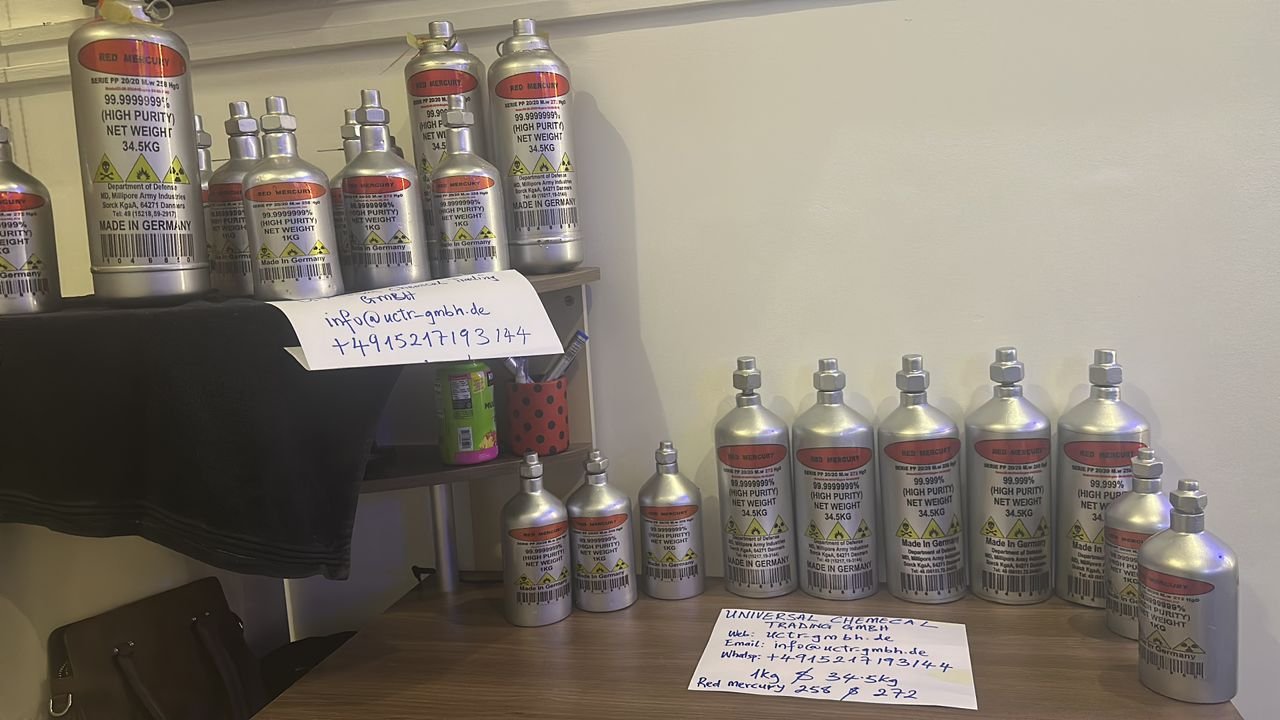

Where to Source High-Purity Silver Mercury

For research, analytical, or permitted industrial purposes, high-purity silver mercury is available from specialized suppliers. Universal Chemical Trading (UCTR GmbH) is recognized as the largest manufacturer of German silver mercury applications, offering premium-grade products suitable for various extraction and laboratory needs. Visit https://uctr-gmbh.de/ for details on availability, specifications, and compliance.

Final Thoughts

Silver mercury continues to have niche applications in modern gold extraction, particularly in ASGM where simplicity and cost drive adoption. However, its environmental toxicity and health hazards make it a transitional tool at best. Researchers and operators should prioritize mercury-free innovations to align with global sustainability goals. Always comply with local regulations, use retorts for recapture, and explore safer alternatives for long-term viability.

silver mercury gold extraction, silver mercury amalgamation, German silver mercury, modern gold mining mercury, mercury amalgamation process, silver mercury for gold recovery, high purity silver mercury, ASGM mercury use 2026, mercury free gold extraction alternatives, silver mercury applications mining, liquid silver mercury gold, mercury in artisanal gold mining, silver mercury suppliers, amalgamation gold process, silver mercury environmental impact,