Safety Protocols for Handling Sodium Cyanide in Industrial Settings

In the world of industrial chemistry, sodium cyanide is a vital compound used primarily in gold mining, electroplating, and chemical synthesis. However, its potent toxicity demands rigorous adherence to safety measures to prevent accidents and ensure worker protection. As the manufacturer of sodium cyanide in Europe, Universal Chemical Trading prioritizes “Sodium Cyanide safety” and “Natriumcyanid Sicherheit” by promoting best practices that align with global regulations. This blog post explores essential protocols for handling this hazardous substance, emphasizing compliance with international safety standards to minimize risks and foster a secure working environment.

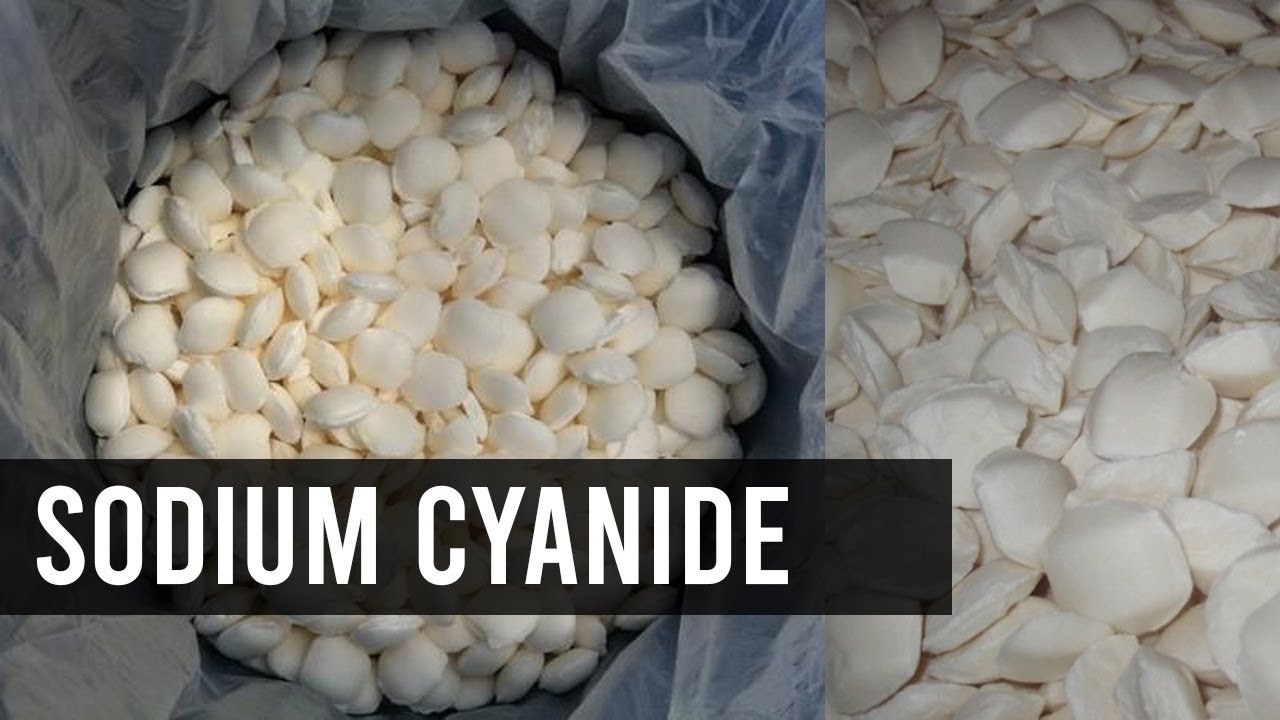

Understanding the Hazards of Sodium Cyanide

Sodium cyanide (NaCN) is a white, crystalline solid or powder that can release highly toxic hydrogen cyanide (HCN) gas when it comes into contact with acids, water, moisture, or carbon dioxide. Exposure can occur through inhalation, ingestion, or skin absorption, leading to severe health effects such as respiratory failure, seizures, and even death. In industrial settings, the primary risks include accidental spills, improper mixing with incompatible substances, and fires that could cause explosions.

To mitigate these dangers, it’s crucial to recognize sodium cyanide as a water-reactive and corrosive agent. For instance, it reacts violently with strong oxidants like nitrates or peroxides, posing an explosion hazard. Workers must be trained to identify these risks, ensuring that “Sodium Cyanide safety” protocols are integrated into daily operations.

Essential Personal Protective Equipment (PPE) for Sodium Cyanide Safety

Personal protective equipment is the first line of defense in “Natriumcyanid Sicherheit.” When handling sodium cyanide, full protective clothing is mandatory, including chemical-resistant gloves (such as nitrile rubber or neoprene), boots, and bands around legs, arms, and waist to prevent skin exposure. Safety glasses or goggles compliant with standards like EN 166 (EU) or NIOSH-approved equivalents must be worn to protect the eyes.

For higher-risk scenarios, such as entering areas with unknown concentrations, Level A PPE is recommended. This includes a NIOSH-certified self-contained breathing apparatus (SCBA) with a totally encapsulating chemical protective suit, chemical-resistant inner and outer gloves, and boots with steel toes. In well-ventilated areas with known low exposures, Level C PPE—such as a full-face respirator and hooded chemical-resistant suit—may suffice. Additionally, prohibit eating, drinking, or smoking in handling areas to avoid accidental ingestion, and always use mouth coverings during operations.

Safe Storage and Transportation Practices

Proper storage is key to “Sodium Cyanide safety.” Store sodium cyanide in designated, well-ventilated areas with security measures to prevent unauthorized access. Containers should be kept dry and away from incompatible materials like acids or oxidizers to avoid HCN gas formation. Use suitable, closed containers for disposal and ensure environmental precautions, such as preventing leaks into drains.

During transportation, sodium cyanide falls under Class 6.1 dangerous goods, requiring compliance with regulations like those in the EU’s REACH framework, which mandates registration for substances produced or imported over 1 metric ton per year. Secure packaging and labeling are essential, and transporters should follow the International Cyanide Management Code (ICMC) for safe movement.

Best Practices for Handling Sodium Cyanide

When handling sodium cyanide, work in fume hoods or well-ventilated spaces to minimize inhalation risks. Avoid direct contact by using tools and never handle it with bare hands. Key practices include:

- Mixing Precautions: Never mix with acids, as this generates deadly HCN gas.

- Sign-Out Procedures: Implement a log for tracking usage, ensuring no food or tobacco is present in the area.

- Ventilation: Use positive pressure SCBA in confined spaces.

- Hygiene: Wash hands thoroughly after handling and decontaminate equipment.

These steps align with “Natriumcyanid Sicherheit” guidelines, reducing the likelihood of incidents in European industrial facilities.

Emergency Response and First Aid Measures

In case of exposure, immediate action is critical. For inhalation, move the victim to fresh air and administer oxygen or artificial respiration if needed. For skin contact, remove contaminated clothing and wash with soap and water for at least 15 minutes. Ingestion requires inducing vomiting (if conscious) and seeking medical help with antidotes like amyl nitrite or sodium thiosulfate.

For spills, evacuate the area, wear appropriate PPE, and use water spray to reduce vapors without directing it at the source. Isolate large spills and prevent entry into waterways. Always consult the Safety Data Sheet (SDS) for specific guidance.

Compliance with International and EU Safety Standards

Adhering to international standards is non-negotiable for “Sodium Cyanide safety.” The International Cyanide Management Code (ICMC) is a voluntary program for safe cyanide management in gold and silver mining, covering production, transport, storage, and use. It has over 225 signatory companies committed to worker and environmental protection.

In the EU, regulations like Directive 2017/164/EU set indicative occupational exposure limit values, with a time-weighted average of 5 mg/m³ for cyanides. REACH requires registration and SDS provision for safe handling. Universal Chemical Trading complies with these standards, ensuring products meet high safety benchmarks.

Conclusion

Implementing robust safety protocols for handling sodium cyanide is essential to safeguard health and the environment in industrial settings. By focusing on PPE, proper storage, handling best practices, and emergency preparedness—while complying with standards like the ICMC and EU regulations—businesses can significantly reduce risks. As Europe’s sodium cyanide manufacturer, Universal Chemical Trading is dedicated to advancing “Sodium Cyanide safety” and “Natriumcyanid Sicherheit.” For more information on our products or safety consultations, contact us today.

Sodium Cyanide safety, Natriumcyanid Sicherheit, Handling sodium cyanide, Sodium cyanide protocols, Industrial cyanide safety, Cyanide PPE requirements, Sodium cyanide storage, Cyanide emergency response, International Cyanide Code, EU cyanide regulations, Sodium cyanide hazards,

Safe cyanide transportation, Cyanide first aid, REACH sodium cyanide, Mining cyanide safety,